Description

Key Features

- Low footprint with optimal accessibility.

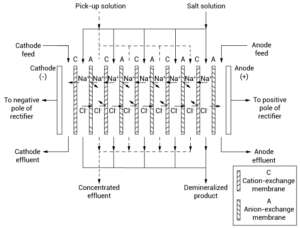

- Flexible installation options like membrane-based and resin-based systems.

- Constructed from 316/L stainless steel, internal surface finish up to 0.38 Ra.

- CGMP, GAMP, and 21 CFR Complaint system design based on ASME, ASTM, BPE, ISPE, WHO, ENVISA, and MHRA, guidelines.

- Permanent Flushing.

- Automatic hot water sanitization, shut down & recirculation mode, maintenance & night mode.

- Flexible system integration with other technologies.

- Designed for robust and safe operation.

- Validation to regulatory and client standards or as per GMP, cGMP, ISPE, USP, EP, JP, IP, etc. guidelines.

- Minimizes waste generation, reuse, and recycling.

- Capability to handle high-temperature ramp Up / Down.

| Feed Water Specifications | |

|---|---|

| Feed Water Conductivity Equivalent, including CO2 and Silica |

< 40 µS/cm |

| Temperature | 41 —113°F (5-45°C) |

| Inlet Pressure | 20 — 100 psi (1.4 — 7 bar) |

| Maximum Free Chlorine (as CL2) | <00.02 ppm |

| Iron (Fe) | <0.01 ppm |

| Manganese (Mn) | <00.01 ppm |

| Sulfide (S-) | <00.01 ppm |

| pH | 4 – 11 |

| Total Hardness (as CaCO3) | <01.0 ppm/td> |

| Dissolved Organics (TOC as C) | <00.5 ppm |

| Silica (SiO2) | <01.0 ppm |

| Technical Fitures | Benefits |

|---|---|

| Green & Energy efficient technology | Lower operating cost |

| Costumized Systems | System most suited for your application |

| Skid mounted design | Lower foot print, saving of production srea |

| Build CIP System | Easy & Fast cleaning |

| Wide choice of membrane MOC & Geometries | Selection of best membrane for your application |

| Complete Turnkey Projects management with process guarantee | One stop solution for all your needs |

FAQs

1. Why Nilsan’s High Purity Water Systems?

![NeroION [M/R Series]](https://nilsan-nishotech.com/wp-content/uploads/2022/03/nero-ion-scaled.jpg)

![NeroSIS [C/H Series]](https://nilsan-nishotech.com/wp-content/uploads/2022/03/nero-sis-400x225.jpg)

![NeroLOOP [T/O Series]](https://nilsan-nishotech.com/wp-content/uploads/2022/03/nero-loop-400x300.jpg)