Drug development section under health sector developed pipelines which were highly dominated by small molecules. These molecules failed to clear the regulatory requirements. Peptides fill a niche between typical small molecule chemicals and the larger proteins. Proteins play an important role as a physiologically active component in our diet. They perform both the protective and regulatory biological functions. These specific protein fragments, which are denominated peptides, may have a positive effect on human health.

Peptides may contain from 3 to 20 amino acid residues per molecule varying widely in their chemical structure and in turn in their biological functions. In addition, they may have anti-protozoal, anti-viral and anti-thrombotic activity, thus, reducing cholesterol levels and body mass.

Encrypted peptides can be found in animal and plant sources, such as milk, dairy products, eggs, fish, oysters, cereals (rice, wheat, buckwheat, barley and corn), soybeans, radish seeds and other protein rich sources. Antioxidant peptides may be applied to oxidative processes since the oxidation results in the production of free radicals (O2,OH,H2O2) during the metabolism which p a critical role in health-related disorders and can lead to heart disease, atherosclerosis, diabetes, cancer and neurological diseases. In food, free radicals may result in the deterioration of quality attributes such as flavour, colour and texture. The antioxidant activities of peptides have the ability to delay or prevent oxidative processes.

Antimicrobial peptides act against a wide variety of pathogenic microorganisms, such as bacteria, fungi and viruses. The role of antihypertensive peptides is in the regulation of blood pressure. Opioid peptides can be considered compounds which may exert effects on the nervous system, similar to opium (morphine). Several peptides with different properties can be obtained and applied to foods and drugs after having their bioactivity evidenced. Therefore, a constant study is required to obtain technology so that real application can be carried out.

Peptide manufacturing can be achieved entirely through chemical synthesis, either in the solution phase, coupled to a solid phase or by the combination of both. Alternatively, peptides can be produced by recombinant microorganisms or by extraction from their natural (plants or animal) source.

Because of several technological and therapeutics properties of bioactive peptides, the production of these biomolecules is a promising approach to be exploited by the food and pharmaceutical industry. Studies on currently available potentially low-price sources for the production of these peptides need to be exploited. Despite the advances achieved by research, further studies are still needed in order to reduce the costs of production, downstream processes and scalability.

Isolation and purification of bioactive peptides are very important to explore their physicochemical properties along with evaluation of the bioactive properties by in vitro and in vivo assays. There is always a trade-off between purity, process cost and process time. The final purity depends on the intended purpose viz; >99% for therapeutic application and 95% for in vitro diagnosis. Thus the purification process needs to be economically viable, as it has a high share of the total production cost.

Irrespective of the upstream production method of choice, downstream processing is a vital step in the manufacturing of peptide pharmaceutical products since it involves the critical steps associated with product isolation and purification. The downstream process purification needs to be simple, minimal step and avoid difficulty, easily reproducible, less expensive and easily scalable. Over the last two decades, membrane processes and chromatography systems have been developed especially for the isolation and purification of peptides varying widely in their sources, quantity and complexity to meet the requirements such as:

- Required level of purity (> 95%)

- Concentration enrichment

- Removal of specific impurities (e.g. toxins from therapeutic products)

- Prevention of catalysis other than the type desired (as with enzymes)

- Prevention of catalysis poisoning (as with enzymes)

- Recommended product specifications

- Enhancement protein stability

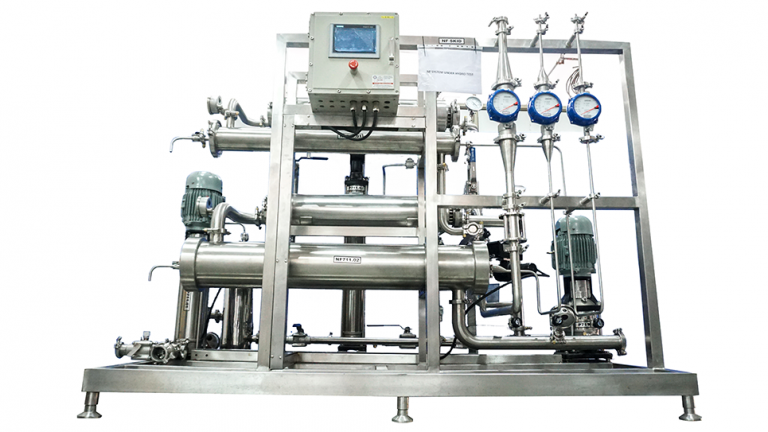

Membrane processes are commonly used processes in the large-scale separation of bioactive peptides which are based on the differences in the permeability of the liquid constituents through a membrane. The driving force applied to the mass transport is partial pressure.

Chromatography is one the most powerful technique to isolate and purify bioactive peptides (> 99.5%) based on the properties of molecules.

| Method | Principle |

| Reverse Phase | Hydrophobicity |

| Ion Exchange | Surface charge |

| Size Exclusion | Size relative to pore size of stationary phase |

| Affinity | Specificity – using ligand |

The purification methods which are effective in laboratories need to be cost effective on large scale. Peptide-based products commercialization is still limited due to the high cost of separation and purification techniques and the lack of systems applicable for industrial scale. Thus, the engineering system partner needs to support at every scale of operation to make this process feasible and economically viable. Also, the partner needs to have a scale-down approach such that the success rate at large scale process development increases many folds.

Why Nilsan Nishotech for your peptide solutions?

Nilsan Nishotech Systems Pvt. Ltd. (NNSPL) has come a long way since its humble beginnings nearly 3 decades ago and established itself as India’s most trusted engineering solutions provider in membrane filtration (MF, UF, NF, RO) and chromatography purification (HPLC, LPLC, preparative, DAC) systems. Their unwavering focus lies in utmost satisfaction to their clients by offering highly differentiated yet customized solutions. Visit the link for knowing the companies journey, milestones and projects handled with numerous clients.

With this expertise in separation technology, NNSPL has provided several clients in the FMCG, Pharma and Nutraceutical industries with Peptide separation solutions.

Advantages of using NNSPL Membrane systems:

- Energy-efficient process

- Low maintenance and operating costs

- Versatile systems – can be used for multiple products

- Inbuilt CIP/SIP capabilities

- Sanitary System design system

- No effluent discharge

- Skid-mounted compact systems & less footprint.

- Attractive CapEx and OpEx over conventional separation/purification methods

- Wide range of membranes – In MF, UF, NF, RO – in different MOC, and in different module designs to meet specific processes.