Dynamic Axial Compression (DAC)

Provides the optimum packed bed density and stability, thereby ensuring optimum separation efficiency and consistent performance for an extended period of time. The column includes a movable piston attached to a hydraulic jack. The piston is used to pack and unpack the column and keep the stationary phase under dynamic compression, ensuring the highest efficiency and bed stability at any scale. Together with Novasep’s unique flow distribution system, and DAC technology enables us to guarantee the same performance (plates/meter, asymmetry) from 50 mm ID to 1.6 m ID.

For applications requiring the use of soft and/or fragile packing materials, the concept of a smart piston has been developed and patented, preventing the crushing of particles or gels. The piston is automatically adjusted with the swelling or shrinkage of the stationary phase to maintain a constant compression over time.

- Best-in-class separation with the highest HETP

- Smart piston to maintain constant pressure

- Optimized packing technology with advanced flow distributors ensures the highest efficiency

- Guaranteed scale-up and performance

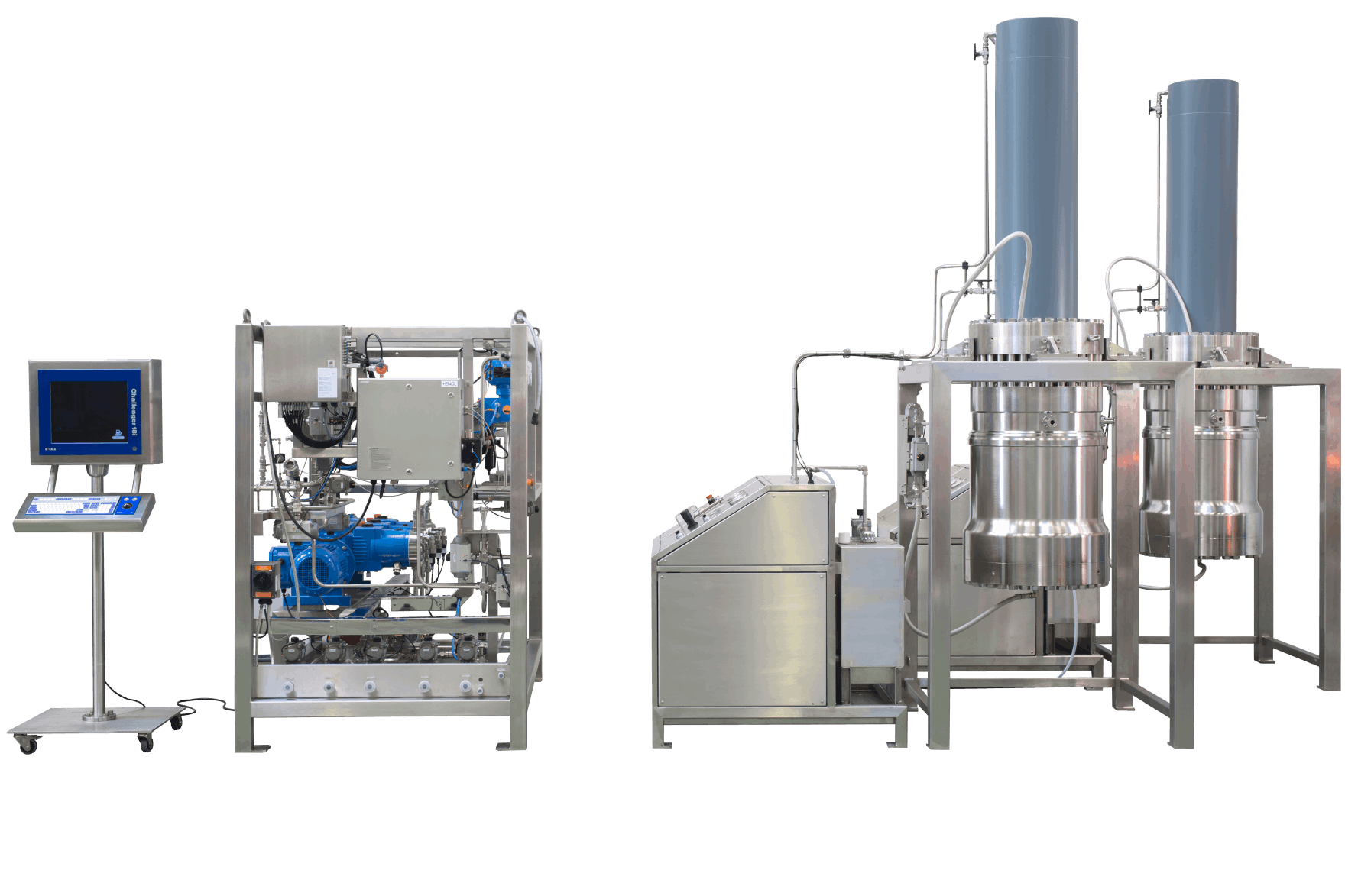

2. Hipersep® Systems

Fully automated Hipersep HPLC systems are designed for process development, pilot-scale, and production-scale chromatographic separations.

- Robust and efficient system design allowing 24/7 continuous operation

- PAT (Process Analytical Technology guidelines of the FDA) compliance with high-performance in-line dilution and gradient systems as well as smart fraction collection control

- High productivity and yield resulting from high accuracy and stability of operating parameters (flow rate, eluent composition, temperature, etc.) as well as excellent process reproducibility

- Easy and fast maintenance

- Validated and user-friendly software for easy start-up, training, and on-site qualifications

- ATEX, GAMP V, 21CFR Part 11, Material certificates for 3.1 & 2.1 CODAP/ASME Compliance

- More than 2500 industrial scale units in operation globally (> 150 installations in India)

- Scalability is ensured using the same design from lab to large industrial units

- Hipersep® systems offer maximum performance with Prochrom® DAC columns

| Prochrom® Hipersep Systems |

Lab I |

Lab II |

S |

M |

L |

XL |

| Flow-Rate Range (L/h) |

06-40 |

20-90 |

090-200 |

150-500 |

300-1000 |

500-2500 |

| Adapted Column Diameter (mm) |

50-80 |

100-150 |

150-200 |

200-450 |

300-590 |

590-1600 |

| Max. Operating Pressure (bar) |

– |

– |

100 |

– |

– |

70 |

| – |

110 |

350 |

Lab II |

30-60 |

100 |

100 |

Injection – Detection – Collection

Features |

Low or high pressure Injection

UV detector (other detector as an option) Automated fraction collection (5 or 10 valves) Column backflush and recycling valves as an option |

| Implementation |

Gen. purpose lab |

Hazardous area rated

(ATEX Zone II – Class 1 Division 2) |

3. Slurry Packing Unit

- Our convenient packing unit safely and reproducibly mixes the stationary phase with an appropriate solvent and then transfers the resulting slurry by gravity or with a pump into the column

- The units are equipped with cleaning-in-place devices

- Different units and volumes are available, depending on the client’s column size.

FAQs

1. How is the preparative Chromatography System useful for you?

Preparative Chromatography Systems are indispensable in industries, facilitating the purification and isolation of compounds critical for pharmaceuticals, biotechnology, food, and chemicals. These systems ensure high-purity products, accelerate drug discovery, and enable large-scale production, contributing to the advancement of research, development, and manufacturing processes across diverse industrial sectors.

2. What are the applications of Chromatography Systems in the food industry?

Chromatography in the food industry is vital for analyzing flavors, additives, contaminants, and nutritional components. It ensures food safety, quality control, and compliance with regulatory standards, maintaining consumer health and satisfaction.

3. Why do you need Chromatography Systems?

Chromatography systems are essential for separating, identifying, and analyzing complex mixtures of compounds. They enable precise detection, purification, and quantification in diverse fields, including pharmaceuticals, environmental analysis, and research, and if your industry includes any related process, we can help with our technologies and furthermore provide Customized Solutions as per your requirements.

4. Why choose Sanitech Engineers?

Sanitech Engineers specializes in the design and manufacture of Membrane Systems and Preparative Chromatography Systems for a variety of sectors, including Pharmaceutical, bio-pharmaceutical, Nutraceutical, Dairy, and Food & Beverages. We have been practicing our technologies for the last three decades and hence, we carry the expertise and solutions to your problems.