Description

Applications

- Pre-purification and intermediate purification of insulin

- Vaccines and viruses

- Proteins such as monoclonal antibodies and blood/plasma fractions

The range, very complete with lab- to large-scale equipment, includes:

- Prochrom®-Bio Columns

- Packing & Unpacking Stations

-

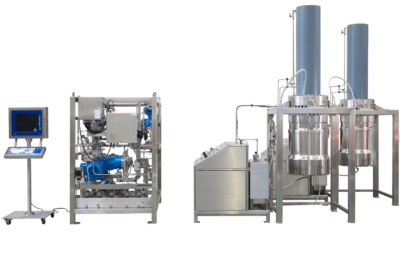

Prochrom® Hipersep-Bio Chromatography Systems

1. Prochrom®-Bio Columns

Prochrom®-Bio columns are the result of Novasep’s experience in developing, supplying, and operating cGMP processes using preparative and process-scale high-performance and low-pressure liquid chromatography columns. Prochrom®-Bio columns’ unique design includes a hydraulically actuated piston and specially designed packing/unpacking valves to provide consistent and optimum performance.

- Standard column diameters range from 150 to 1,400 mm

- Material of construction: acrylic or stainless steel

- 5 bar operating pressure

- Easy and fast maintenance

- DESP or ASME code of construction

- Sanitary design

- Operator safety: contained packing & unpacking operations, column design, etc

- Easy and fast packing and unpacking

- Optimum and reproducible performance

- Guaranteed scale-up

- Versatility: excellent and proven performance with a wide variety of resins

2. Packing and Unpacking Systems

Novasep offers 3 models of packing and unpacking stations adapted to the column size. These stations provide:

- Highest efficiency for any kind of resin thanks to the specially designed packing & unpacking valves and the hydraulically actuated piston

- Reduced downtime with fast and easy packing and unpacking operations

- Minimized repacking time of recycled resin which needs only a small amount of buffer for unpacking (2 to 3 CVs)

- High level of reproducibility due to automated functions

- Pre-programmed or easily configurable packing & unpacking methods

| Column Name | Column Diameter (mm) | Maximum BedVolume (L) | Packing & Unpacking Station | Prochrom® Hipersep-Bio System | Flow-Rate Range (LHP) |

|---|---|---|---|---|---|

| LP150.500.VE 5 | 150 | 8 | PU S | Pilot | 1- 50 |

| LP200.500.VE 5 | 200 | 12 | PU S | S | 1- 150 |

| LP300.500.VE 5 | 300 | 32 | PU S | S | 1- 150 |

| LP450.500.VE 5 | 450 | 70 | PU S / M | M | 20-500 |

| LP600.500.VE 5 | 600 | 125 | PU M | M | 20-500 |

| LP800.350.VE 5 | 800 | 150 | PU M / L | L | 50 – 1200 |

| LP1000.350.VE 5 | 1000 | 230 | PU L | L | 50 – 1200 |

| LP1200.350.VE 5 | 1200 | 330 | PU L | XL | 200 – 3000 |

| LP1400.350.VE 5 | 1400 | 450 | PU L | XL | 200 – 3000 |

3. Prochrom® Hipersep-Bio Chromatography Systems

Novasep’s fully automated Prochrom® Hipersep-Bio LPLC systems are designed for process development, pilot-scale, and production-scale downstream processing. Scalability is ensured using the same design from lab to large industrial units. Prochrom® Hipersep-Bio systems suit any biochromatography columns and offer maximum performance with Prochrom®-Bio columns for bed volumes from 1 to 450 L and column diameters from 150 mm to 1,400 mm I.D.

- Reduced investment with an exceptional turn-down ratio due to the optimal design and choice of components. Very accurate in-line dilution control based on volume or conductivity means reduced tank and space requirements

- High productivity and yield result from a high accuracy and stability of operating parameters (velocities, buffer composition, temperature, etc.) as well as excellent process reproducibility.

- Reliability of instrumentation and “open design” (providing easy access to parts) means reduced maintenance and, thus, reduced operating costs

- Validated and user-friendly software for easier start-up, training, and on-site

| Prochrom® Hipersep-Bio Systems | |||||

|---|---|---|---|---|---|

| Standard Features | Pilot | S | M | L | XL |

| Flow Rate Range(LPH) | 1-50 | 1-150 | 20-500 | 50-1200 | 200-3000 |

| Pressure Rating(bar) | 5 | ||||

| Buffer Preparation | High Performance, PAT-Compliant in-line dilution | ||||

| Fraction Collection | 5 to 10 Valves, multiple automated fraction collection modes | ||||

| Detection | Air,pressure, pH, conductivity, UV | ||||

| Control System | Siemens WinAC platform-iFix SCADA | ||||

FAQs

1. How is the preparative Chromatography System useful for you?

Preparative Chromatography Systems are indispensable in industries, facilitating the purification and isolation of compounds critical for pharmaceuticals, biotechnology, food, and chemicals. These systems ensure high-purity products, accelerate drug discovery, and enable large-scale production, contributing to the advancement of research, development, and manufacturing processes across diverse industrial sectors.

2. What are the applications of Chromatography Systems in the food industry?

Chromatography in the food industry is vital for analyzing flavors, additives, contaminants, and nutritional components. It ensures food safety, quality control, and compliance with regulatory standards, maintaining consumer health and satisfaction.

3. Why do you need Chromatography Systems?

Chromatography systems are essential for separating, identifying, and analyzing complex mixtures of compounds. They enable precise detection, purification, and quantification in diverse fields, including pharmaceuticals, environmental analysis, and research, and if your industry includes any related process, we can help with our technologies and furthermore provide Customized Solutions as per your requirements.

4. Why choose Sanitech Engineers?

Sanitech Engineers specializes in the design and manufacture of Membrane Systems and Preparative Chromatography Systems for a variety of sectors, including Pharmaceutical, bio-pharmaceutical, Nutraceutical, Dairy, and Food & Beverages. We have been practicing our technologies for the last three decades and hence, we carry the expertise and solutions to your problems.